2010 Lotus Evora 414E Hybrid Concept

|

Price |

-- |

Production |

-- | ||

|

Engine |

1.2 liter 3-cylinder hybrid |

Weight |

-- | ||

|

Aspiration |

-- |

Torque |

-- | ||

|

HP |

410 hp |

HP/Weight |

-- | ||

|

HP/Liter |

-- |

1/4 mile |

-- | ||

|

0-62 mph |

under 4 seconds |

Top Speed |

-- |

(from Lotus Press Release) The 80th International Geneva Motor Show sees Lotus Engineering unveil the Lotus Evora 414E Hybrid concept, a high performance technology demonstrator with a plug-in series hybrid drive system and new technologies for enhanced driver involvement.

The Lotus Evora 414E

Hybrid, so-named because this latest environmentally-focused

technology demonstrator from Lotus Engineering produces 414 PS (306

kW) of power, promises breathtaking performance from a highly

efficient propulsion system. The concept showcases new developments

in plug-in, range-extended electric propulsion, new electronic

technologies to enhance driver involvement, the adaptability of the

Lotus Versatile Vehicle Architecture (VVA) that underpins the Evora

414E Hybrid and a dramatic new roof system and interior concept from

Lotus Design. Through all of these aspects it ultimately

demonstrates the exceptional ability of Lotus Engineering to

integrate and develop advanced technologies for exciting, efficient,

high performance niche vehicles.

The range extended electric drive of the Evora 414E Hybrid consists

of two electric motors driving each of the rear wheels independently

via single speed geartrain, integrated into a common transmission

housing, thus enabling torque vectoring for stability control of the

vehicle. Electrical power is stored in a lithium polymer battery

pack optimised for energy density, efficiency and high power demand,

mounted in the centre of the vehicle for stability and safety.

Additional range is provided by the Lotus Range Extender engine, an

optimised 1.2 litre, three-cylinder engine, designed specifically

for series hybrid vehicles. The drivetrain is designed to combine

astonishing performance with efficient, low emissions driving.

Driver involvement is enhanced by the incorporation of HALOsonic

Internal and External Electronic Sound Synthesis technologies from

Lotus and Harman International, which provide sound contouring

within the cabin and improve pedestrian safety outside the vehicle.

Integrated with the HALOsonic technology, the Evora 414E Hybrid also

showcases a brand new technology from Lotus Engineering, a sports

mode that simulates a 7 speed, paddle shift transmission that

combines exceptional driver involvement for a hybrid sports car and

optimised energy recuperation.

The Evora 414E Hybrid has been designed to highlight Lotus’

innovative electric and hybrid vehicle technology without

distracting from the pure sportscar character of the Evora. The

solution is innovative, instantly recognizable, beautiful and

sporty. It demonstrates Lotus DNA.

Dr Robert Hentschel, Director of Lotus Engineering said: “Innovation

has always been at the heart of Lotus and is needed now more than

ever. The Evora 414E Hybrid is the perfect demonstration of Lotus

Engineering’s core competencies: lightweight architectures,

efficient performance, electrical and electronics integration and

driving dynamics. The technology demonstrator represents an

encapsulation of the advanced technologies that Lotus Engineering

continues to develop to overcome the current environmental

challenges facing the automotive industry and showcases the future

direction that the sector is taking and why Lotus Engineering is

perfectly placed to lead the technological development in this

area.”

The Drivetrain

For the Lotus Evora 414E

Hybrid, Lotus Engineering has developed a highly efficient, high

performance drivetrain system consisting of twin motors each limited

to providing 152 kW (207 PS/204 hp) of power and 400 Nm (295 lbft)

of torque to each wheel via independent, single speed, reduction

transmissions integrated into a single housing, enabling torque

vectoring dynamic control of the vehicle.

The vehicle energy storage system is made up of the latest Lithium

Polymer battery chemistry providing 17 kWH energy storage capacity.

The battery pack is optimised for energy density, efficiency and

high power demand, with over 100 kW discharge capability.

The Lotus Range Extender engine provides 35 kW (48 PS/47 hp) of

power at 3,500 rpm via the integrated electrical generator and

features an innovative architecture comprising an aluminium

monoblock construction, integrating the cylinder block, cylinder

head and exhaust manifold in one casting. This results in reduced

engine mass, assembly costs, package size and improved emissions and

engine durability. The engine uses an optimised two-valve, port-fuel

injection combustion system to reduce cost and mass and can be

operated on alcohol-based fuels and/or gasoline. The generator

converts mechanical energy to electrical energy to replenish the

battery pack charge and provides additional vehicle range in a small

light weight package. The generator is also used as a motor to start

the range extender engine. The low mass of the range extender unit

(85 kg) and compact package makes it ideal for the series hybrid

drivetrain in the Evora 414E Hybrid.

All the operation and management of the range extender engine, the

power management of the batteries and motor control are controlled

by Lotus’ electronic control units and software systems. Full energy

management of all the operating systems is the key to maximising

performance and operation while minimising energy consumption and

CO2 emissions.

For everyday commuting journeys, up to 35 miles can be travelled

using battery power. The battery can be charged overnight using a

conventional domestic mains supply through a socket concealed by the

rear number plate. This permits the vehicle to operate with zero

tailpipe emissions. For longer journeys, exceeding the battery

capacity, the highly efficient range extender engine is used as a

generator to supply the motor with electrical power and top up the

battery.

Lotus has used its own vehicle simulation tools to determine the

size, capacity, power and performance of all the components in the

drivetrain system to optimise the system operation. Overall this is

far more energy efficient, weight efficient and cost effective than

fitting the vehicle with a larger and more expensive battery, which

for the majority of short journeys is a redundant weight, which

increases energy requirements. With regard to the total lifetime CO2

emissions of the vehicle, including the energy required to

manufacture and run it, the range extender solution has a lower

overall CO2 footprint than a fully electric car of comparable

performance and operating range running with a larger battery.

The Package

The Lotus Evora 414E

Hybrid structure is the same award-winning, versatile vehicle

architecture used on the Lotus Evora. The low volume architecture

was designed with the upmost flexibility in mind. The Evora 414E

Hybrid is a perfect example of how to integrate a compact packaged

drivetrain, with excellent performance and range, while using this

underpinning. The complete chassis has remained unchanged from the

Evora which maintains the structural integrity and strength

performance of the original car.

The structure progresses the Lotus ‘bonded and riveted’ technology

with new and unique extrusions and folded panels, whilst providing

production build modularity and lower cost repairs. The chassis has

been designed for scalability so that it can be extended in width,

length and height. The strength and stiffness of the low volume VVA

chassis can be modified cost effectively by varying the wall

thickness of the extrusions, without altering the exterior

dimensions. The ability to lengthen or shorten extrusions with the

option to tailor the chassis stiffness vastly increases the number

of vehicles that can be developed from this vehicle architecture.

Driving Dynamics

The Lotus Evora 414E

Hybrid offers exhilarating, all-round dynamic performance and takes

advantage of Lotus developed torque vectoring dynamics. Torque

vectoring, which is the capacity to generate different torques at

each of the driving wheels, is particularly suited to electric

vehicles and significantly reduces the conflict between stability

and response.

A key benefit of separate motors to drive each rear wheel

individually is that this facilitates a much higher level of vehicle

dynamics control. Driving the wheels with different levels of torque

can not only generate all the capabilities of a conventional ESP

system using energy regeneration as opposed to brake application,

but it can also actively drive each wheel forward at different

rates, producing a turning moment at the rear of the vehicle in

addition to the steering input.

This can be used to enhance low speed manoeuvrability and ease of

parking but can also be used to produce a much greater level of

straight line high speed stability. Incorporating lateral sensors

the system also provides stability control capabilities and levels

of steering response normally only associated with heavy and

expensive rear steer systems. This can provide automatic correction

of both understeer and oversteer characteristics. In addition, the

standard method to provide high speed stability of designing the

rear wheels to toe-in is not required as the torque vectoring system

automatically provides this stability control, with toe-in

increasing rolling resistance, lowering fuel economy and increasing

tyre wear. Lotus‘ long history of active suspension control provides

the core capability to develop this technology and provides

extraordinary driving pleasure on the Evora 414E Hybrid.

Driver Interaction

The Evora 414E Hybrid

provides less of a psychological step change for people familiar

with high performance cars compared to other electric and hybrid

sports cars. The car has a simulated paddle shift gear change

offering ultra quick gear changes reminiscent of a dual clutch

transmission, while actually single speed. This enhances the driver

interaction with the vehicle and provides a driving experience

similar to current internal combustion engine high performance

sports cars. The Evora 414E Hybrid uses a column mounted paddle

shift to simulate the gear change and a synthesised engine sound

changes frequency with virtual gear selection. The drive torque is

also modulated to simulate a physical feeling of a gearshift jolt.

The virtual gearshift simulation, like a conventional gearbox, is

used to change the driving characteristics and response of the

vehicle. The most significant aspect that this offers the driver is

the ability to control the vehicle deceleration by simulating engine

braking through a virtual downshift in gears. Unlike true engine

braking, the Lotus system does not dissipate the energy of the

moving vehicle through internal engine friction but uses the

electric motors to regenerate the energy back into the battery.

While many electric and hybrid vehicles provide engine braking, this

is generally at a fixed rate or preselected rate. In some driving

situations this can either be too aggressive, slowing the vehicle

unnecessarily, or too light, requiring additional braking

application. The Lotus system effectively allows the driver to

select the appropriate level of regeneration by simulating stepping

down by one, two or even three gears. The simulation of engine

braking through both the gear noise change and the retardation of

the vehicle is fully intuitive to a driver familiar with a

conventional gearbox. The simulated gearchange capability can be

selected for greater driving involvement or switched off for more

relaxed driving.

The Evora 414E Hybrid uses the Lotus Engineering and Harman

International developed HALOsonic suite of noise solutions. The

first of which is Electronic Sound Synthesis. This generates engine

sounds inside the vehicle through the audio system where it provides

an exciting sports sound in line with the brand and nature of the

vehicle together with a high level of driver feedback in an

intuitive manner. In addition, it also generates sound on the

outside of the vehicle through speakers mounted at the front and

rear to provide a warning to increase pedestrian safety, which is

especially important for electric and hybrid vehicles which can be

difficult to hear at slower speeds.

There are four driver selectable engine sounds currently on the

vehicle, two of which have been designed to have characteristics of

a multi-cylinder conventional V6 and V12 engine. There is also a

futuristic sound and a combination of a conventional engine and a

futuristic sound, enhancing the brand identity of the vehicle as a

step forward in electric vehicle design.

The addition of this Lotus patented simulated gearshift concept not

only provides for an exciting and involving driving experience that

customers would expect from a Lotus, but also enhances the driver’s

control of the vehicle while providing the capability for more

efficient operation through a greater use of energy regeneration.

The Design

The distinctive colour

scheme and ‘floating’ roof have been carefully designed to accent

the cars electric vehicle technology whilst complementing the iconic

lines of the Evora.

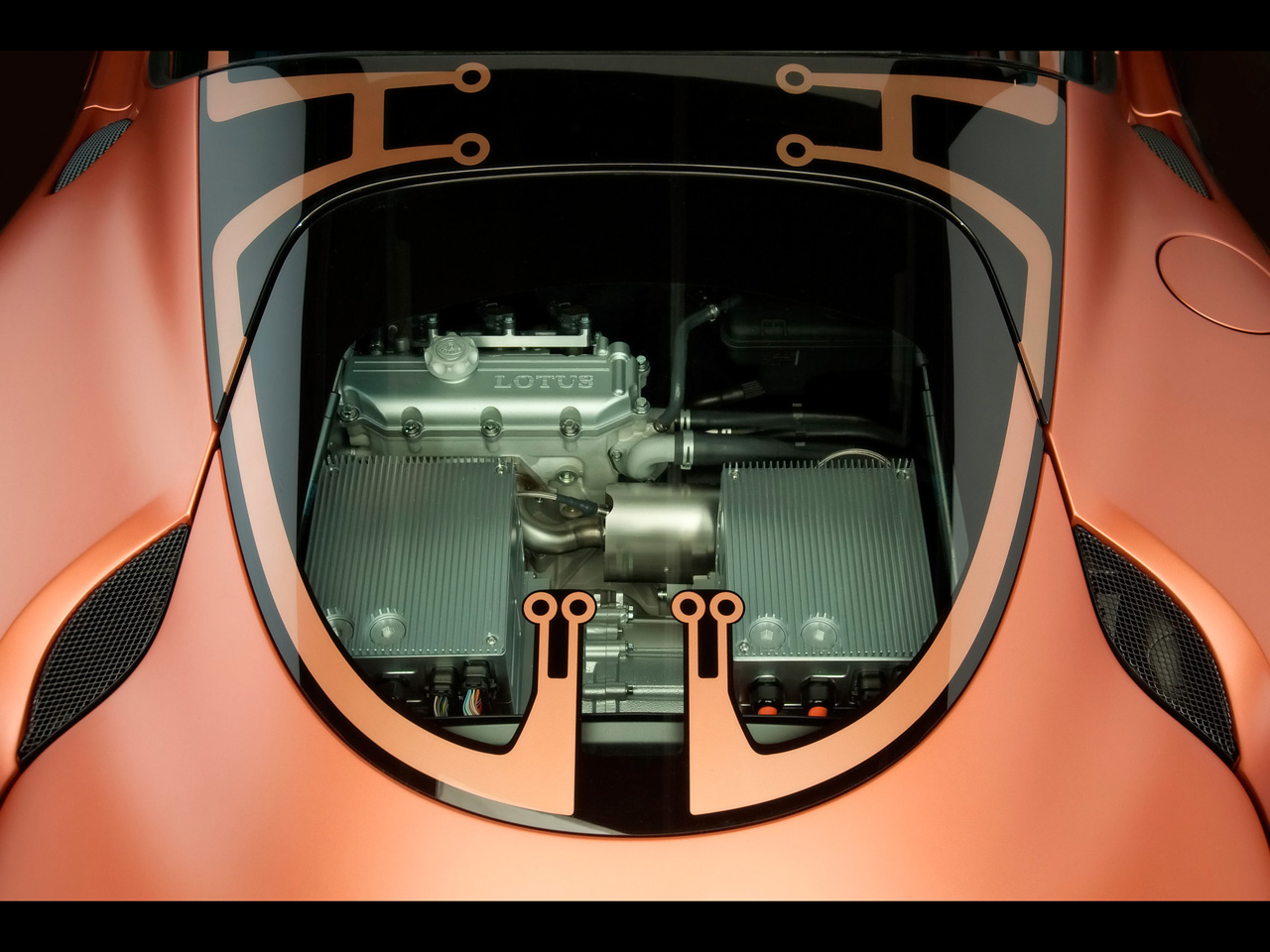

Copper, a colour often associated with electrical systems, has been

chosen for the car’s exterior and interior. A contemporary satin

finish paint is complemented by electrical circuit inspired graphics

that highlight the car’s key feature lines and the unique glazed

roof panel. The newly extended glazed zone integrates seamlessly

with the existing forms of the Evora whilst showcasing the key

components behind the hybrid and electric vehicle technology.

The signature copper theme is consistently carried throughout the

car from the dramatic seat stripes and instrument panel inserts to

the copper callipers that nestle behind the carbon grey forged

wheels. Inside the cabin a sense of quality and richness has been

created by carefully juxtaposing the different tactile qualities

intrinsic to leather, Alcantara and metal.